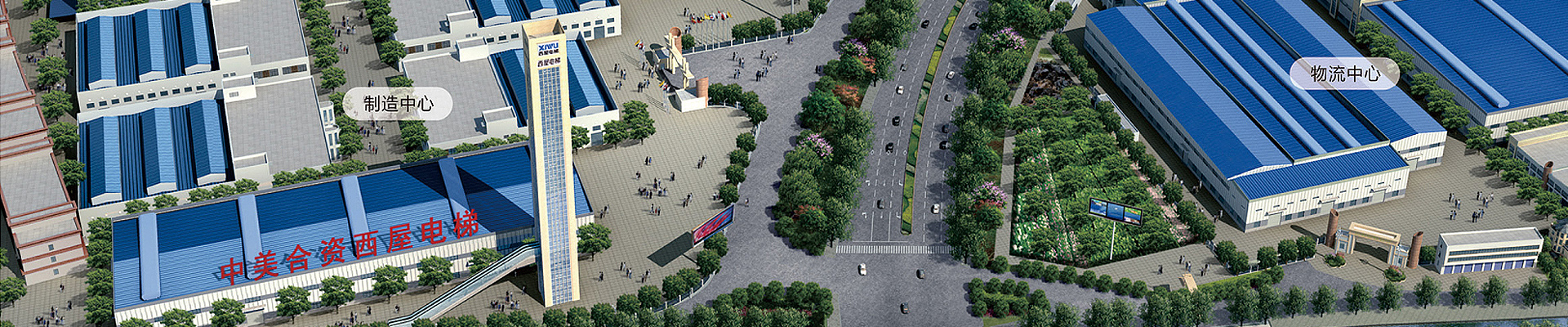

XiWu Elevator Co., Ltd. is a Sino-American joint venture modern elevator manufacturing enterprise integrating research and development, manufacturing, sales, installation, maintenance and transformation. The company is equipped with a full set of first-class modern production and manufacturing systems such as CNC laser cutting machine, automatic door panel production line, multi-station CNC punching machine, CNC bending machine, processing center, spraying line, etc. The annual production capacity of 8000 sets has been formed. At present, Westinghouse elevator products have been produced in large and medium-sized cities throughout the country, and the company's products have entered Southeast Asia, the Middle East and other countries in bulk. In order to meet the major regional market demand, timely and effective service customers, the company plans to build two production bases in the next five years to Tianjin as the base of North China and Xinjiang as the base of Northwest (Central Asia) region, and finally achieve 20,000-30,000 sets of annual production capacity.

While actively exploring the market, XiWu is also aware of the importance of technology, talent and brand to the development of enterprises. In order to bring Westinghouse elevator to a new level in the field of scientific and technological research and development, and further enhance the competitiveness of Westinghouse elevator brand in the industry market, the company follows the principle of "complementary advantages and common development". Through negotiation and negotiation, the company has established a long-term cooperation and development agreement with Building Mechanization Research Branch of China Academy of Building Science and Tianjin University, and jointly established "Elevator Intelligent Research Center of Building Machinery Research Branch of China Academy of Building Science" and "Elevator Industry-University-Research Base of Tianjin University".

Quality is the primary productive force. XiWu Elevator always adheres to the principle that "special equipment quality assurance system is implemented in the whole process, and national standards only set the lower limit of process value", and guides the quality level from the source with the design and development far beyond the national standards. Therefore, the resulting inspection and testing standards must be strict and reliable, and the production process must also be high-standard controllable. The corresponding equipment, raw materials, production, installation, maintenance and other links can be improved through continuous system audit and continuous review and improvement to promote quality progress.